In June, the exclusively designed steel mount for the CAURUS Sensor, necessary to secure the sensor between two longlines required for external loads under a helicopter, passed material testing. The break resistance test conducted at the Material Testing Lab of the Technical University of Munich thus validates the safety of the sensor longline mount for external loads of up to 5.5 tons.

The sensor longline mount was developed by Thaler Engineering specifically for CAURUS Technologies and is made of high-strength tempered steel. It can withstand particularly high tension. This is important when the CAURUS Sensor is mounted between a helicopter and a water container during firefighting missions. The sensor longline mount is an optimized version of a previous model, which was designed for a water container load of up to 2.5 tons. In order to render the CAURUS sensor compatible with maximum loads of up to 5.5 tons, a new longline mounting device had to be engineered that would be able to not only carry more weight while retaining the same size but would also be more lightweight.

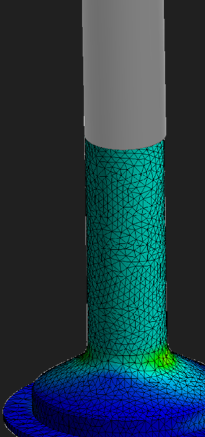

This is where Thaler Engineering came into play, using CAD design and modern Finite Element Simulation to develop a load-bearing design for the dumbbell-shaped sensor mount. Bernhard Thaler, Managing Director of Thaler Engineering and development engineer, summarizes the process: “By modifying the design, we were able to achieve optimum stress distribution while retaining the size of the sensor longline mount. To make concrete predictions about component properties, we used simulation-driven design. Using Finite Element Simulation, we calculated how the components would behave later under operating loads. This enabled us to build a highly optimized sensor mount.”

The connector was then tested at the TUM Material Testing Lab to hold a weight of up to 27 tons or 5.5 tons multiplied with a safety coefficient of 5. The aim was to establish the point of deformation and breaking of the sensor longline mount and to ascertain its stability and safety in carrying heavy external loads. With the positive test results, CAURUS Technologies can now document the safe use of its sensor on large helicopters carrying up to 5.5 tons of water and container frequently used during forest firefighting missions.

About Thaler Engineering

The company offers development services for mechanical engineering projects in such interdisciplinary areas as mechatronics or optomechanics. With 20 years of experience in the development of production automation and research platforms, the company specializes in quick and cost-effective product development and optimization based on simulation-driven technology that allows for early prediction of product behaviour in live use situations.